Pinellas Plant

State: Florida

Location: Clearwater

Time Period: 1957-1997

Facility Type: Department of Energy

Facility Description

The AEC purchased the Pinellas Plant in 1957 from General Electric. The plant produced precisely-timed neutron generators used to initiate nuclear explosions. As older nuclear weapons were removed from the national stockpile, the accelerator-type neutron generators produced at Pinellas gradually replaced polonium-beryllium initiators manufactured at the Mound site. Pinellas also fabricated other weapons components including lightning-arrestor connectors, specialty capacitors, crystal resonators, magnetics, and optoelectronic devices.

In September 1994, Pinellas stopped producing weapons-related components and began to change its mission to environmental management. The Department of Energy (DOE) transferred much of the Pinellas production capability to the Kansas City Plant in Missouri and the Sandia National Laboratory in New Mexico. The DOE completed cleanup of the site in December 1997.

Throughout the course of its operations, the potential for beryllium exposure existed at this site, due to beryllium use, residual contamination, and decontamination activities.

CONTRACTORS: Lockheed Martin Specialty Components, Inc.(1992- 1997); General Electric Company (1957-1992)

Listing

Pinellas Plant is listed as a Department of Energy (DOE) site under the EEOICPA.

Compensation

As of 05/03/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Pinellas Plant is $39,239,119.

Pinellas Plant Workers

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442, Buffalo, NY

Site Description and History

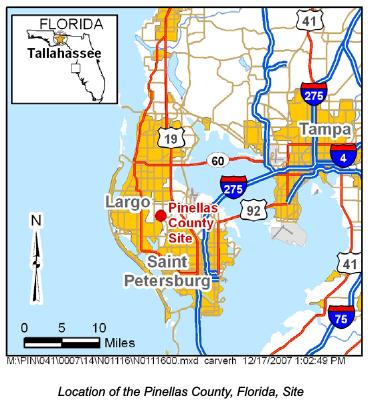

The Pinellas County site is located in Largo, Florida, about 10 miles north-northwest of St. Petersburg and across Tampa Bay from the city of Tampa. General Electric Company constructed the original Pinellas Plant in 1956. In 1957 General Electric sold the facility to the U.S. Atomic Energy Commission, a predecessor agency of the U.S. Department of Energy (DOE) but continued to operate the plant under a 25-year contract. The purpose of the facility was to develop and manufacture weapons components for the nation’s nuclear weapons program.

The Pinellas Plant ceased operations in 1997, and DOE and the Pinellas County government jointly redeveloped the site for commercial use. The County currently owns the facility, which is now called the Young – Rainey Science, Technology, and Research (STAR) Center. The STAR Center houses more than 30 businesses that include a variety of administrative and light manufacturing operations.

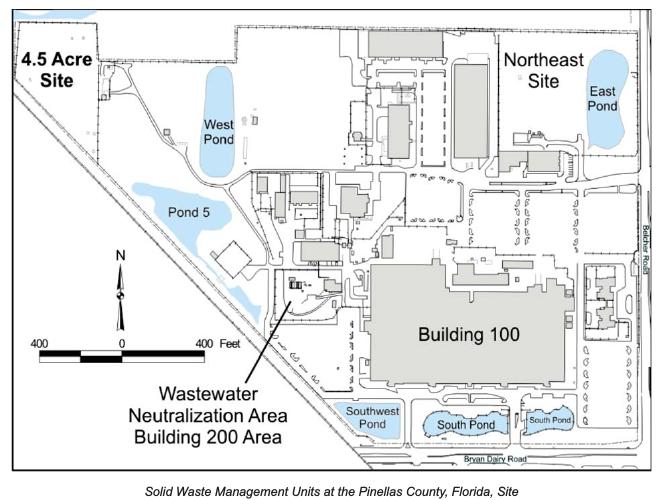

As a result of historical waste disposal practices, portions of the subsurface and the shallow surficial aquifer are contaminated with organic solvents and metals. The contaminated areas are designated as solid waste management units (SWMUs). A total of 17 SWMUs were identified and investigated at the Pinellas site. DOE recommended, and the U.S. Environ- mental Protection Agency (EPA) Region IV and Florida Department of Environmental Protection (FDEP) approved, no further action decisions for 13 of these SWMUs. Currently, four SWMUs—the Old Drum Storage Area, the Industrial Drain Leaks–Building 100 Area, the Northeast Site, and the Wastewater Neutralization Area—have contamination in the surficial aquifer groundwater at levels that exceed protective standards. Two SWMUs, the Old Drum Storage Area and the Industrial Drain Leaks–Building 100 Area, have been combined and are now known as the Building 100 Area. In addition to the four SWMUs, the 4.5 Acre Site is a former part of the Pinellas Plant. DOE owned this parcel from 1957 to 1972, at which time it was sold to a private landowner. DOE’s Office of Legacy Management (LM) is responsible for the administration of DOE activities at the 4.5 Acre Site and the STAR center.

Northeast Site

Parts of this area were used for the disposal of drums of solvent waste in the 1950s and 1960s. Over time, the drums leaked this waste into the subsurface. The drums and contaminated soil were excavated in 1995. Efforts to clean the contaminated groundwater, such as pumping the water to the surface for treatment, were conducted in the 1990s and early 2000s. These actions helped to control the contaminant plume but had limited effect at reaching cleanup goals. Primary contaminants at the Northeast Site include trichloroethene, methylene chloride, dichloroethene, and toluene.

In an effort to expedite the cleanup of this site, DOE implemented innovative methods for remediating groundwater and soils.

After evaluating the different methods available for treating the source of contamination at the Northeast Site, DOE selected a combination of electrical heating and steam injection. In electrical heating, an electrical current is applied to electrodes inserted into the subsurface, and as the current passes through the soil between the electrodes, electrical resistance heats the soil. Steam injection involves injecting steam from a boiler into the subsurface through injection wells or generating steam when hot water is injected around the heating electrodes. The electrical current and steam travel through the subsurface, heating the soil, the groundwater, and the waste material. As the temperature of the soil rises, the volatile organic contaminants are converted to vapor, which is captured and pumped to the surface through vacuum extraction wells. The recovered vapor is then treated at the surface. This interim action to remove contaminant source material was completed in September 2006.

Subsequent groundwater monitoring demonstrated that a small amount of contaminant source material remained in the subsurface. Therefore, in 2008 and 2009, approximately 3,700 cubic yards of contaminated soil were excavated using the large-diameter auger method and disposed of off site.

Currently, all remediation activities are complete and DOE is conducting closure monitoring of groundwater under the FDEP’s risk-based corrective action (RBCA) regulations.

Building 100 Area

Building 100, the largest building at the STAR Center, covers approximately 11 acres. During the period of DOE ownership, the building was used for offices, laboratories, and production facilities. Groundwater contamination at the Building 100 Area resulted from historical leaks of underground drain lines located beneath the building and from leaks or spills at the former drum storage pad near the northwest corner of the building. The drum storage pad was removed in 1983, and use of the underground drain lines was discontinued in 1989. The major groundwater contaminants of concern are trichloroethene, dichloroethene, vinyl chloride, and 1,4-dioxane.

A groundwater extraction and treatment system operated at the Building 100 Area from 1997 to 2005. Contaminated groundwater was extracted through two recovery wells located at the northwest corner of the building, and treated at the surface using an air-stripper treatment system.

The Building 100 Area was evaluated for potential closure under global RBCA, but it was concluded that long-term monitoring is currently the best solution. During the course of monitoring, DOE discovered two groundwater contaminant plumes that extend beyond the property boundaries, one to the south and one to the east. Therefore, DOE is evaluating options for plume management while continuing long-term groundwater monitoring to verify that the contaminant plume is stable.

Wastewater Neutralization Area

The Wastewater Neutralization Area includes the area south of Building 200, near the industrial wastewater neutralization facility. The industrial wastewater neutralization facility currently receives sanitary and industrial wastewater from the STAR Center industrial operations, neutralizes the water, and discharges it to the publicly owned treatment works.

In 1997, arsenic, trichloroethene, and vinyl chloride were detected in the groundwater at concentrations above federal and state regulatory limits. Arsenic is the principal contaminant of concern; trichloroethene and vinyl chloride concentrations are at low levels. The origin of the contamination in this area is not known.

Groundwater cleanup at the Wastewater Neutralization Area began in 1997 and continued into 2005. Contaminated groundwater was pumped from the subsurface and piped to the industrial wastewater neutralization facility, where the water was discharged to the publicly owned treatment works. Discharge from the industrial wastewater neutralization facility is sampled regularly to confirm that contaminant concentrations in the wastewater are below regulatory limits.

Extensive soil sampling was conducted at the Wastewater Neutralization Area in 1998 to identify areas of soil with elevated arsenic contamination. In 1999, approximately 22 cubic yards of soil was removed from the areas with the highest arsenic concentrations. This action removed the source of arsenic contamination.

FDEP issued written approval to proceed with the closure of the Wastewater Neutralization Area in May 2007. Currently, DOE is working with FDEP and the STAR Center to establish institutional controls at the STAR Center. Institutional controls will ensure the protection of human health and the environment by restricting access to shallow soil and groundwater. Site closure will proceed once these controls are in place.

4.5 Acre Site

The 4.5 Acre Site was sold to a private landowner in 1972, and DOE currently leases the site while groundwater remediation is ongoing.

During the period of DOE ownership, the 4.5 Acre Site was used for the disposal of drums containing waste resins and solvents. This practice resulted in the contamination of groundwater in the shallow surficial aquifer. The main contaminants of concern are trichlorethene, dichloroethene, vinyl chloride, and benzene. The drums and the contaminated soil were removed in 1985.

In 1990, a groundwater extraction and treatment system was put into operation at the 4.5 Acre Site. Contaminated groundwater was extracted through seven recovery wells at the site, treated with an air stripper to remove the volatile organic contaminants, and discharged to a publicly owned water treatment system. For several years, this treatment reduced the mass of the contaminant plume and contained it within the boundaries of the site. By 1997, however, the treatment system no longer effectively reduced concentrations of groundwater contaminants.

A dual-phase extraction system was installed at the site in 1997 to replace the groundwater extraction system. The dual-phase system consisted of a vacuum pump linked to 22 extraction wells. The dual-phase aspect of the system referred to the system’s capability to recover both contaminated water and contaminant vapors from the subsurface. The dual-phase system was an improvement over the groundwater extraction system because it used a vacuum to help move the groundwater and recover vapor from subsurface areas not reached by the groundwater extraction system.

By the end of 1998, the dual-phase system had treated approximately 9.45 million gallons of contaminated groundwater. This system was effective at removing high concentrations of contaminants, but it became less effective as contaminant concentrations decreased.

To treat the remaining lower concentrations of contaminants, DOE selected a type of enhanced bioremediation called biosparging. Bioremediation helps naturally occurring subsurface microorganisms break down organic contaminants into non-toxic compounds. A biosparging system, consisting of three horizontal wells 500 feet long, was installed at the site in late 1999 to enhance aerobic bioremediation. Aerobic bioremediation takes place in the presence of oxygen. The system injects air into the subsurface; the air passes through the groundwater and provides an oxygen-rich environment for the aerobic microorganisms, increasing their ability to break down organic compounds. The effectiveness of the biosparging system was limited by preferential pathways in the subsurface, which caused the injected air to contact only a small portion of the aquifer. Also, high chemical-oxygen demand in the aquifer material used up most or all of the oxygen in the injected air before aerobic conditions could be attained. The biosparging system was shut down in May 2003.

Subsequent groundwater monitoring showed that elevated contaminant concentrations remained in the subsurface. In response, DOE conducted an investigation in the summer of 2007 to determine if a source of contaminants was present in soil. Nearly 1,200 soil samples were collected and analyzed to characterize a 1-acre area of the site, and results indicated that a contaminant source was present.

In 2008 and 2009, approximately 2,500 cubic yards of contaminated soil were excavated using the large- diameter auger method and disposed of off site, thereby removing the source of contamination.

Currently, all remediation activities are complete and DOE is conducting closure monitoring of groundwater under the FDEP’s RBCA regulations.

DOCUMENTS

Technical Basis Documents

Pinellas Plant – Introduction

Effective Date: 04/18/2011, Revision: 01

Pinellas Plant – Site Description

Effective Date: 04/01/2011, Revision: 02

Pinellas Plant – Occupational Medical Dose

Effective Date: 10/13/2011, Revision: 01

Pinellas Plant – Occupational Environmental Dose

Effective Date: 07/15/2011, Revision: 01

Pinellas Plant – Occupational Internal Dose

Effective Date: 07/18/2016, Revision 02

Pinellas Plant – Occupational External Dose

Effective Date: 04/28/2011, Revision: 01

Technical Information Bulletins

Revision to Pinellas Plant Site Profile

Date: April 20, 2016

SC&A

ISSUE RESOLUTION MATRIX FOR PINELLAS PLANT

Original Date: June 2, 2009,

Updated: March 15, 2016

PINELLAS SITE PROFILE REVIEW ISSUES MATRIX

Date: 12/14/2015

Review of the NIOSH Site Profile for the Pinellas Plant Site

September 15, 2006

DCAS

Share this:

EEOICPA CLAIMS

If you or your parent worked any of the DOE or AWE facilities listed on this website and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor.

Call EEOICPA Counsel Hugh Stephens at 1-800-548-4494, email hstephens@stephensstephens.com, or fill out the form below whether or not you have already filed a claim and even if your claim has been accepted or denied.

Contact Us

"*" indicates required fields

*note: Submission of this form does not establish an attorney-client privilege.

Contact Us

Address:

2495 Main Street, Suite 442

Buffalo, New York 14214

Phone:

(716) 852-7590

Fax:

(716) 852-7599

After Hours:

(716) 208-3525

Email Us:

R. William Stephens, Esq.

R. Hugh Stephens, Esq.

Lisa P. Neff, Esq.